ALtracs® Plus

Specification

-

Overview

- The self-tapping screw for light metal

- Lightweight construction suitability: The optimised thread geometry of the ALtracs® Plus facilitates the use of smaller and shorter screws, but with consistently high strength values

- The ALtra CALC® prognosis programme for pre-dimensioning of joints saves time and effort for individual component testing.

- High clamp loads and long term stability, even under high dynamic and thermal stress

- Up to 40% costs saving through omission of work steps for screw and component

- Easy design engineering with the EJOT® ALtra CALC prognosis programme

- High vibration resistance without additional safety elements

- High assembly safety due to low installation and failure torque

- In case of repairs a metric screw can be used

Hotline

Applications Engineer

„Specialist“ for light metal

EJOT ALtracs® Plus screws are thread-forming fasteners developed for maximum strength values in light alloy assemblies and other non-ferrous metals such as zinc, copper or brass. The ALtracs® Plus is designed for direct assembly into cast holes. Compared to metric screws significant cost savings can be realised because the number of work steps is reduced (e.g. thread cutting). ALtracs® Plus is the improved version of the ALtracs® screw and it achieves strength values which are comparable to metric screw joints of the strength category 10.9.

Individual design assistance

The new EJOT ALtra CALC® prognosis programme, which is based on the mechanical parameters of many thousand applications and test assemblies, is a valuable support for the pre-dimensioning of direct assembly into light metal. The software contains the fastening parameters of the ALtracs® Plus screw according to material and pilot hole dimension. This way valuable time can be saved during the design phase of a component.

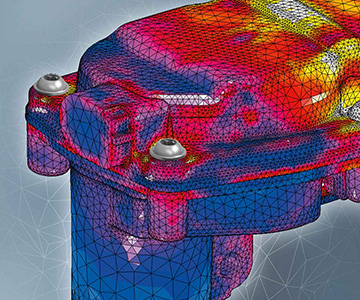

CAE services - component optimisation and individual design engineering assistance

We also support you during the development phase with our CAE services. With the help of innovative calculation and simulation tools we estimate the behaviour and the effect of our fastening elements on your component under various loads and then give you the respective recommendation. It is possible to calculate the clamp load relaxation of individual screw joints and also to analyse the behaviour of the complete assembly. More...

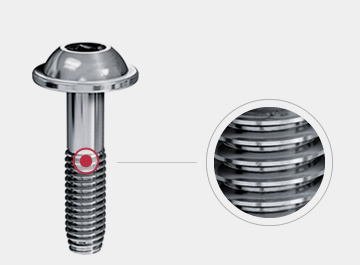

Optimised thread design

The thread geometry plays an important role for direct assembly into light metal, since the different material strength properties of steel and light metal require a special design of the steel screw. The 33° screw flank angle forms a considerably stronger female thread compared to 60° threads. The female thread in the weaker light metal material is strengthened by the larger thread root which causes a balanced strength ratio. The asymmetric thread flank results in optimal material displacement and creates a large thread engagement area.

Safe assembly

The resulting low installation and high failure torques of the ALtracs® Plus facilitate a broad range for secure installation with simple pneumatic and electric drivers. Torque and torque angle controlled tightening processes are also possible beyond yield strength of the screw since the failure mode stripping or screw fracture can be specified. The circular cross section in combination with various installation depths (1 to 2,5 x d) allows a high amount of flexibility in the choice of the appropriate fastening system. The sharp thread flanks of the ALtracs® Plus in connection with the non-circular thread forming zone enable centred alignment and easy tightening of the screw even in cast holes.

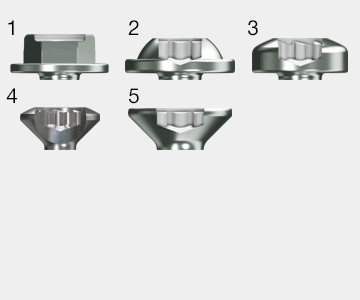

ALtracs® Plus WN 51 Head Styles and Drives

WN5117 hexagon flange head

WN5151 round washer head with TORX PLUS®/AUTOSERT

WN5152 pan head with TORX PLUS®/AUTOSERT

WN5153 oval countersunk head with TORX PLUS®/AUTOSERT

WN5154 flat countersunk head with TORX PLUS®/AUTOSERT

For detailed information, please refer to the EJOT company standard.

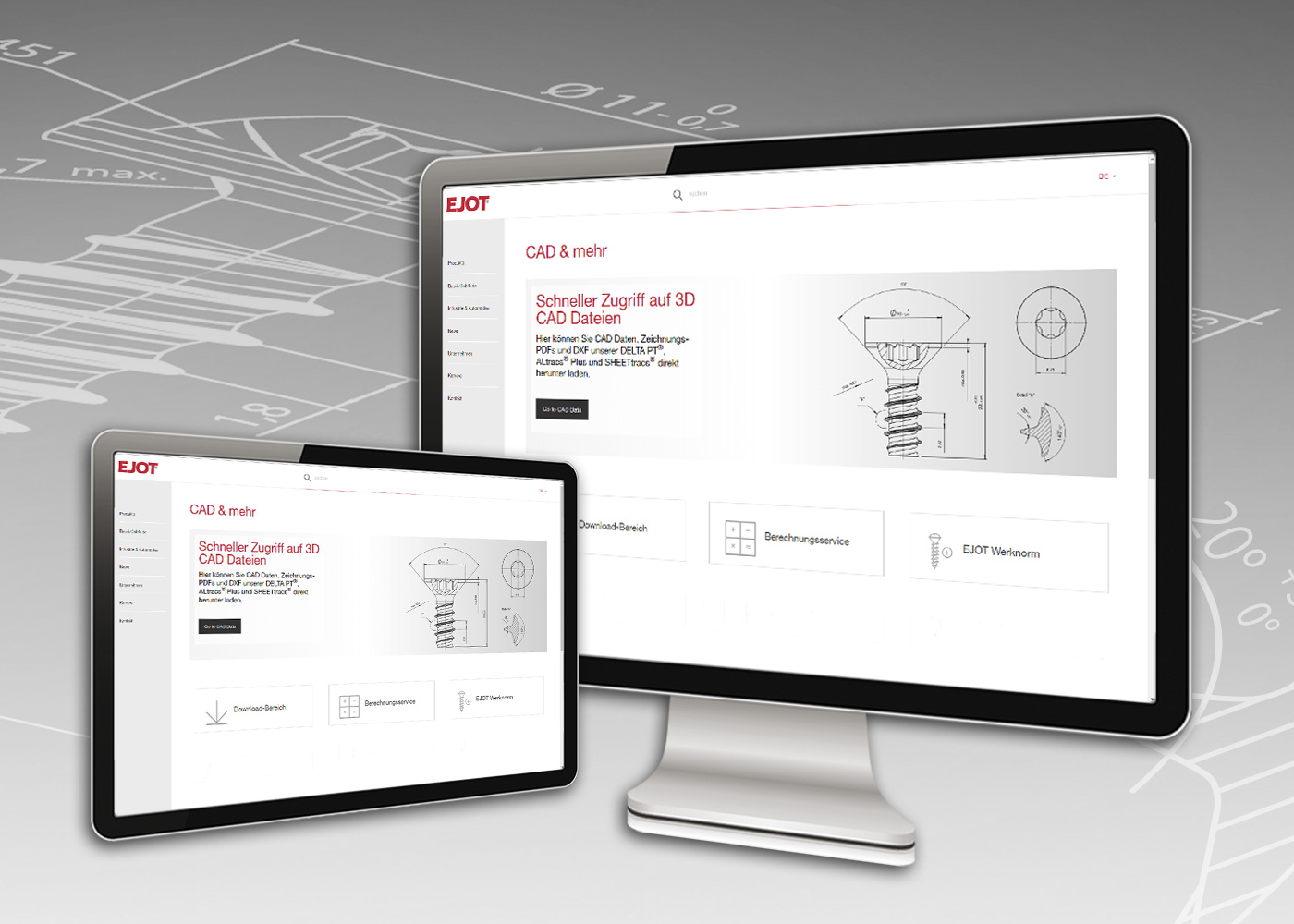

You can download these in our service area "CAD & more".

Click here to register: "CAD & more"

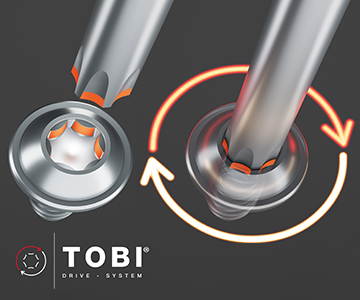

TOBI® Drive-System - The high-performance screw drive system

- Secure hold without magnetic bits or vacuum systems

- Axial alignment of screw and bit

- Longer bit life due to enlarged contact area (up to 70x higher)

- Reverse compatibility with standard internal hexalobular bits

- More information