MAXXtip®

スペック

-

Overview

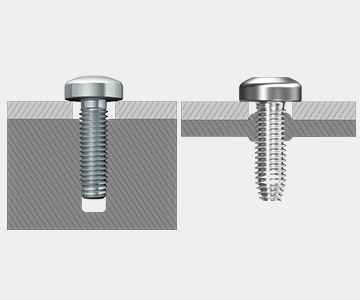

- Process-reliable direct fastening into:

- ultra-high strength steels

- cast iron- Completely insensitive to hydrogen embrittlement - even with galvanic coatings

- Removable joint

Thread forming solution for (ultra) high strength materials

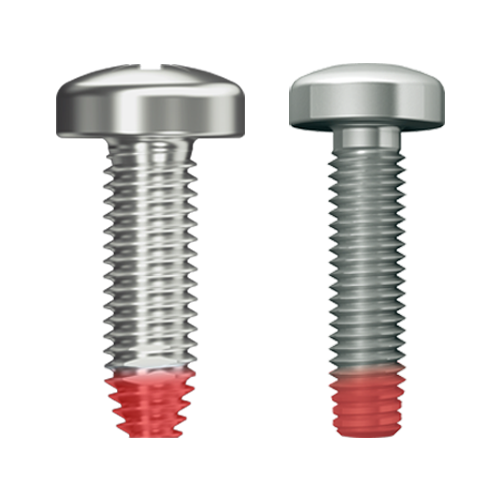

EJOT MAXXtip® combines a carbo-austempered shank with an ultra hard screw tip. This unique combination allows completely new options for direct fastening into (ultra) high strength materials.

Due to the carbo-austempered microstructure (strength similar to 10.9) in the load-bearing area MAXXtip® screws are insensitive to hydrogen embrittlement. Therefore, galvanic surfaces can be applied without tempering leading to a thread flank hardness of at least 750 HV* in the forming area.

*In case of Zn flake surfaces, baking leads to a reduced thread flank hardness in the forming area of at least 600 HV.

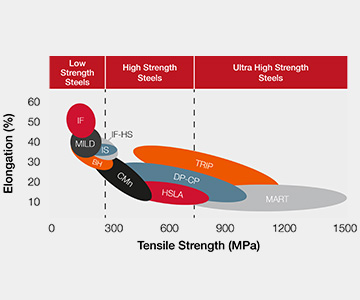

Main application fields of EJOT MAXXtip®

(ultra) high strength steel sheets (at least UTS of 1200 MPa) using the thread types

- SHEETtracs® up to 2 mm

- Spiralform® analogous to DIN 7500

cast iron (GJS und GJL) using the Spiralform® thread type